3D & 2D CNC ROUTING

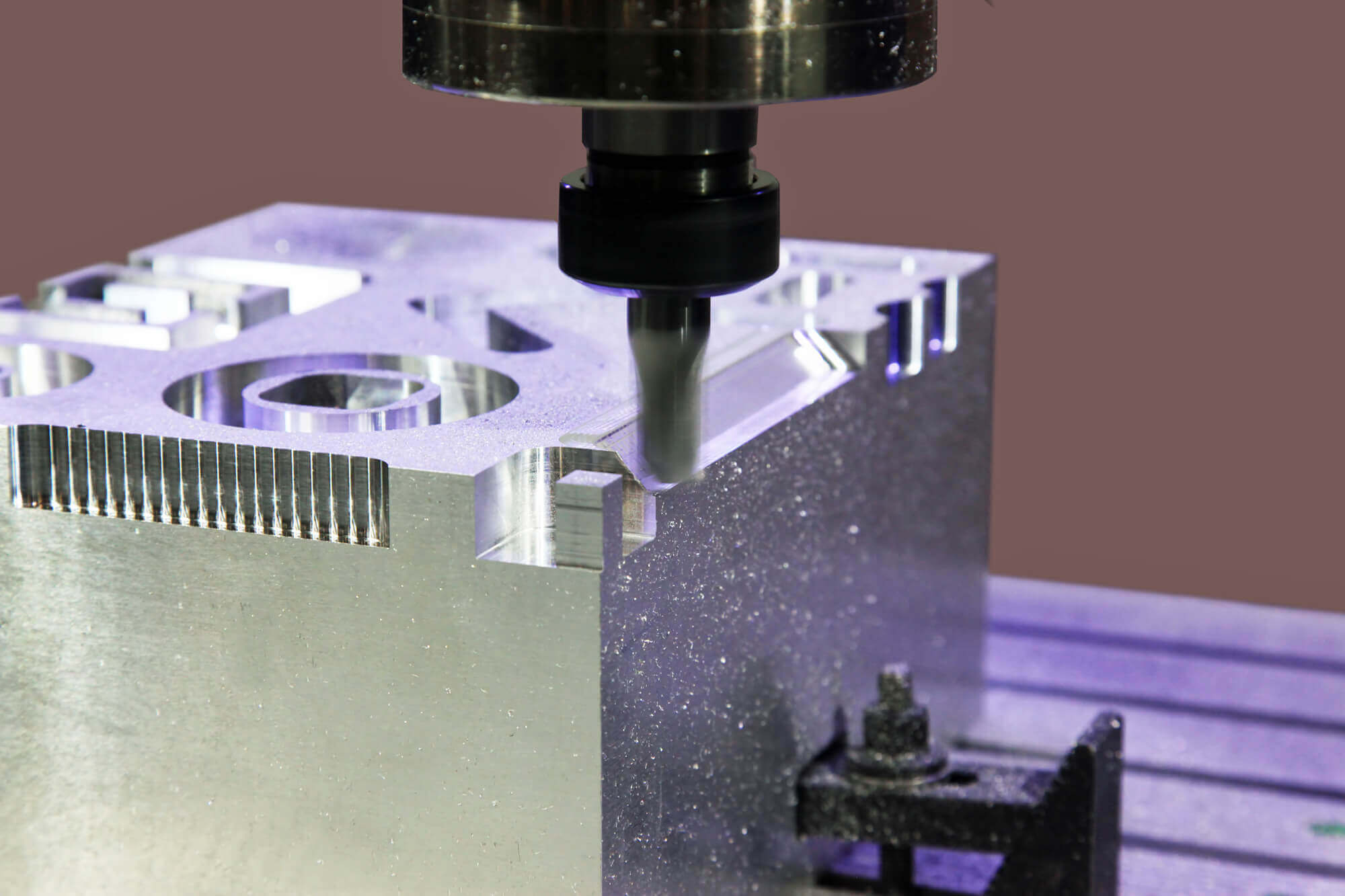

The CNC experts at Green Oak can execute any 3D Routing task with precision and strict attention to detail. We use high-speed automated 3D routers that can be used to cut metal or plastic. Our machines offer a high level of accuracy, and its 3-axis capability can push routing possibilities even further. 3D routers are a necessary part of any machining company’s toolset, and we utilize ours to their fullest extent.

Our 5ft x 10ft table, a 3D CNC router takes a piece of material –metal or plastic- and trims it to an exact measurement based on the client’s specifications. There are multiple steps to this process. Once the design is entered into the CAD/CAM software, the process begins and the router starts working. The process of cutting happens automatically. The term “3D” means the router can cut on 3 different axes, which means there is very little that the router cannot do. With next to no limits, our 3D routers can cut any shape our customer desires. Since our routers are able to cut in three dimensions, 2D routing is also available as a result.

Green Oak Tool offers a wide range of high-performance routing and engraving machines suited to a wide variety of applications. These applications can include profiling of control panels, cutting of 2D and 3D parts for fabrications, and full 3D milling for the creation of prototypes, models and molds.

3D CNC routing can be used by mold makers, aerospace component manufacturers, automotive component manufacturers, display manufacturers, and a wide range of other industries.

3D CNC routers can offer advantages over most other CNC processes for machining metals.

-

Large format processing areas

-

Full 2D and 3D machining capability

-

High RPM routing spindles

-

Simple user operation

-

Cost advantages

Our CNC routers are ideal for cutting aluminum, aluminum extrusions, and other metals such as steel, stainless steel, brass and copper. CNC routers have the capability of creating virtually any shape, design, or logo. We can easily cut and duplicate parts with high precision. The advantage that CNC Routing has over other cutting methods is that the depth is controllable. This enables the cutting of grooves and adding shoulders, as well as performing countersink operations.

CNC Design and router cutting process

We draw the design geometry in AutoCAD, and then export them to a tool path program. If the drawings are already in CAD, then they can be forwarded to us. The CAD file may contain all the panels on one drawing, or separate files for each part. After upload, the parts are nested onto a plate to ensure minimal material waste. Then the program is built and sent to the router for cutting. Vacuum pressure holds larger parts to the table when being cut. Smaller parts may require screws or special fixtures to be held in place. A bit tool changer allows the machine to change tools automatically, reducing overall cut time.

Green Oak Tool